MC4 connectors are the industry-standard, weatherproof plugs designed to connect solar panels safely and securely outdoors. They feature IP65/IP68 ratings to resist water and dust, handle up to 1000V and 50A, and are made from durable, UV-resistant plastics. These connectors guarantee reliable, quick connections for solar arrays in various environments. If you want to understand how they work and why they’re essential, you’ll find useful details as you explore further.

Key Takeaways

- MC4 connectors are industry-standard solar connectors designed for secure, waterproof connections in outdoor solar systems.

- They feature a 4mm pin, quick-locking mechanism, and high IP ratings (IP65/IP68) for weather resistance.

- Capable of handling up to 50A and 1000V DC, meeting safety standards like IEC 62852.

- Made from durable, flame-retardant plastics and corrosion-resistant materials for long-term outdoor performance.

- Easily connect solar panels and system components with minimal fuss using simple push-and-click installation.

What Are MC4 Connectors and Why Are They Important?

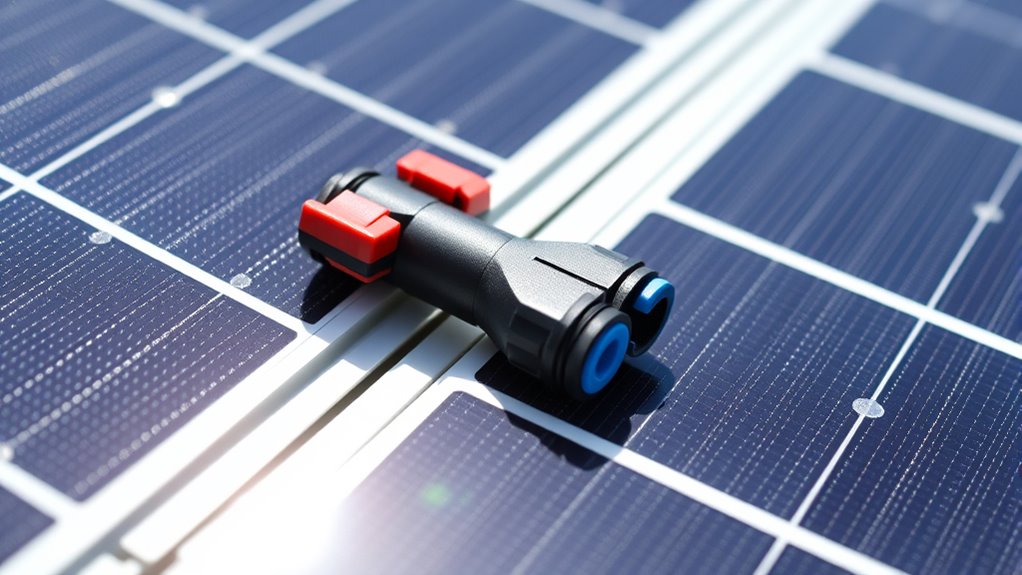

Have you ever wondered what makes solar panel connections reliable and efficient? That’s where MC4 connectors come in. These single-contact connectors are designed specifically for solar applications, ensuring a secure and stable connection between panels and other system components. The “MC4” abbreviation stands for Multi-Contact, 4mm pin diameter, highlighting their standardized size. They’re waterproof and UV-resistant, perfect for outdoor use in harsh weather conditions. The male connector features a pin, while the female has a socket, allowing for easy pairing. As the industry’s universal standard, MC4 connectors simplify installation and maintenance. Their robust design minimizes power loss and prevents connection failures, making them essential for maximizing solar system performance and longevity. European cloud innovation is driving sustainable and secure solutions in energy infrastructure, including solar technology. Understanding the compatibility of these connectors with various solar panels can further improve system efficiency and ease of setup. Additionally, the standardized size helps ensure compatibility across different brands and models, streamlining the installation process. Proper wiring techniques and adherence to safety guidelines are also crucial for optimal system performance.

Key Design Features of MC4 Connectors

The key design features of MC4 connectors guarantee they perform reliably in outdoor solar applications. They are weatherproof, with a tight seal that reduces electrical resistance and prevents water ingress. Made from flame-retardant, UV-stabilized materials like PPO and M-PPE, they withstand harsh sunlight and temperature fluctuations. They are also designed with robust construction to endure physical stresses and environmental exposure over time. The easy connect-disconnect mechanism uses a snap-click locking system, ensuring secure connections and quick setups. Contacts are crafted from copper alloy with tin plating, promoting low contact resistance and durability. These features enable minimal power loss, typically under 0.5%. Additionally, their standardized design allows seamless compatibility across various panels and systems. Weatherproof design ensures durability in outdoor conditions, and the use of UV-stabilized materials enhances their longevity in sunlight exposure. The standardized design also simplifies the process of system expansion or maintenance. The integration of secure locking mechanisms further enhances safety during installation and operation. These features collectively enable minimal power loss, typically under 0.5%. Overall, these design features ensure MC4 connectors deliver consistent, safe, and efficient performance in demanding outdoor environments.

Electrical Ratings and Performance Standards

Understanding the electrical ratings of MC4 connectors helps you make certain of safe and efficient solar setups. These connectors typically handle currents up to 50A and voltages of 1000V DC, with some models rated even higher. Always verify that your connector’s limits match your system’s requirements to prevent performance issues or safety hazards. electrical ratings are crucial for ensuring compatibility and safety in your solar installation. Additionally, understanding connector specifications can help you select the appropriate components for your system’s unique needs. Knowing lifetime and durability factors can also ensure your connections remain reliable over time and under various environmental conditions. Considering free floating design elements may influence connector performance in outdoor settings, ensuring longevity and stability. Moreover, paying attention to performance standards can guarantee your connectors meet industry safety and quality benchmarks.

Current and Voltage Limits

Solar connectors are designed to handle specific current and voltage levels to guarantee safe and efficient energy transfer. You need to be aware of these limits to prevent damage and assure optimal performance. For example:

- They typically support currents of 30A, with some models reaching 50A or 70A, depending on wire gauge.

- The voltage ratings usually max out at 1000V DC, but Type 2 or UL-certified versions can handle up to 1500V.

- Contact resistance remains low at about 0.35mΩ, minimizing power loss during operation.

- Proper connection integrity is essential to maintain performance and safety in solar systems. Ensuring electrical ratings match your system’s requirements helps avoid potential issues.

- Adhering to performance standards ensures that connectors operate reliably under specified conditions. It is also important to verify that the connectors comply with relevant safety certifications for optimal reliability.

- Understanding current and voltage ratings is crucial for selecting the right connectors for your specific solar installation to avoid overloads.

Knowing these limits helps you avoid overheating, electrical failure, and potential safety hazards. Always check your connector’s specifications before installation to match your system’s current and voltage requirements accurately.

Industry Compliance Standards

Industry compliance standards guarantee solar connectors meet strict safety, performance, and durability criteria. These standards ensure your connectors can handle high voltages and currents reliably over time. For example, they typically specify a voltage rating of up to 1500V DC and current ratings between 30A and 70A, depending on wire gauge. They also set limits on contact resistance, ensuring minimal power loss. Waterproof and UV-resistant ratings like IP65/IP68 confirm their durability against harsh outdoor conditions. Compliance with IEC 62852 and third-party approvals such as TUV SUD verify that these connectors meet international safety and performance benchmarks. These standards make sure your solar system operates efficiently, safely, and lasts for years, providing peace of mind for residential, commercial, or portable solar setups. Performance standards ensure consistent operation and long-term reliability. Additionally, adherence to these standards often involves rigorous testing for electrical ratings and environmental resilience, further guaranteeing product longevity. Recognizing these industry standards helps consumers select dependable connectors that meet global safety and performance requirements.

Durability and Environmental Protection Capabilities

Solar connectors are built to withstand harsh outdoor conditions, ensuring reliable performance over time. They resist UV rays, moisture, and temperature fluctuations, so your system stays protected. Think of these features as shielded armor for your setup. For example:

Solar connectors offer durable, weather-resistant protection for reliable outdoor performance.

- IP65/IP68 ratings keep water and dust out, even during heavy rain or submersion.

- Operating temperatures from -40°C to +85°C let them perform in extreme climates without faltering.

- Flame-retardant materials like UL94-V0 grade prevent fires and maintain safety.

- Material durability ensures the connectors remain intact and functional despite prolonged exposure to outdoor elements. Additionally, their weather-resistant design helps prevent corrosion and electrical faults, extending the lifespan of your solar system. Proper sealing techniques further enhance their protection against environmental hazards, ensuring long-term reliability.

These design elements work together to prevent corrosion, electrical faults, and damage, so your solar system remains efficient for years. You can trust that your connectors are prepared for outdoor challenges, providing peace of mind and long-term durability.

Typical Applications and Use Cases

You’ll find MC4 connectors widely used in various setups, from residential rooftops to large-scale solar farms. They’re ideal for linking individual solar panels into an array, enabling quick and secure connections. In residential systems, you’ll use MC4 connectors to connect panels to inverters or charge controllers, simplifying installation. Commercial and utility-scale projects rely on them for high-voltage arrays, ensuring reliable, watertight connections in outdoor environments. Portable applications, like RVs, campers, or boats, benefit from their easy plug-and-play design, allowing quick setup and disassembly. MC4 connectors also support series connections, which increase system voltage for efficiency. Their compatibility with most solar panels and quick connect-disconnect features make them the go-to choice across diverse solar power installations and applications.

Compatibility With Solar Panel Systems and Other Components

MC4 connectors are designed to be universally compatible with most solar panel systems and related components. This means you can easily connect panels from different brands, ensuring seamless integration. Picture these three scenarios:

- Connecting a new solar panel to your existing system with minimal fuss, thanks to standard sizes and locking mechanisms.

- Incorporating adapters like MC4-to-XT60, enabling compatibility with power stations and off-grid setups.

- Interlinking multiple panels in series or parallel configurations, maintaining consistent voltage and current flow.

Thanks to IEC 62852 compliance and third-party approvals, MC4 connectors work reliably across various brands and system designs. This standardization simplifies setup, repairs, and expansions, making your solar project straightforward and flexible.

Installation and Handling Tips for MC4 Connectors

When installing MC4 connectors, make sure you connect them properly to avoid electrical issues. You also need to guarantee a waterproof seal to prevent water ingress and damage over time. Handling and maintaining these connectors regularly will keep your solar system running smoothly and efficiently.

Proper Connection Techniques

Proper connection techniques for MC4 connectors are essential to guarantee safety, efficiency, and long-term performance of your solar system. First, verify your connectors are clean and free of debris before connecting. Second, align the male and female parts correctly, avoiding forced connections that can damage the seals. Third, push the connectors together firmly until you hear a click, confirming the lock is secure. Always handle connectors with dry, insulated gloves to prevent static or electric shocks. Double-check that the locking mechanism is fully engaged and that there’s no visible gap. Properly connected MC4s maintain waterproof seals and electrical integrity, ensuring your solar setup works safely and efficiently over time.

Ensuring Waterproof Seal

To guarantee a waterproof seal with your MC4 connectors, focus on clean, dry surfaces before connecting. Make sure both the male and female ends are free of dirt, dust, and moisture, as debris can compromise the seal. Inspect the O-rings and sealing gaskets for any damage or wear—replace them if necessary. When connecting, firmly push the connectors together until you hear the snap-click, ensuring the seal is tight. Avoid forcing connections or connecting in wet conditions. After joining, double-check that the locking mechanism is fully engaged. Properly aligned and clean surfaces, combined with secure locking, prevent water ingress and maintain the integrity of your solar system’s waterproof protection.

Handling and Maintenance

Handling and maintaining MC4 connectors properly is essential for ensuring reliable connections and long-term performance. To keep them in top shape, follow these tips:

- Always keep connectors clean and dry before connecting, avoiding dirt or moisture that can cause poor contact.

- When disconnecting, grip the connectors firmly by the housing, not the cable, to prevent damage.

- Regularly inspect for cracks, corrosion, or wear, and replace damaged connectors immediately.

Additionally, avoid excessive pulling or twisting on cables, and store unused connectors in a cool, dry place. Proper handling prevents moisture ingress, maintains waterproof seals, and guarantees optimal electrical performance. By following these simple steps, you’ll extend the lifespan of your MC4 connectors and maintain a safe, efficient solar system.

Common Variations and Accessories for MC4 Connectors

Various variations and accessories for MC4 connectors enhance their versatility and guarantee compatibility across different solar setups. You might encounter extension cables, which allow you to connect panels farther apart without losing efficiency. T-branches and Y-branches enable you to split or combine strings, making system expansion easier. Waterproof covers and protective boots safeguard connectors from dirt, moisture, and UV damage in harsh environments. Locking clips or quick-release tools make disconnection simple for maintenance or troubleshooting. Adapter kits, such as MC4-to-XT60 or MC4-to-SO-239, expand compatibility with different equipment. Some accessories include crimping tools and specialized connectors for different wire gauges. Using the right variations and accessories ensures your solar system remains reliable, efficient, and adaptable to future upgrades.

Frequently Asked Questions

How Do MC4 Connectors Prevent Water Ingress in Harsh Weather?

You can trust MC4 connectors to prevent water ingress thanks to their weatherproof design. They feature a tight seal that keeps moisture out, even in harsh conditions. The waterproof and UV-resistant materials, along with a snap-click locking mechanism, guarantee a secure connection. Plus, their IP65/IP68 ratings mean they’re built to withstand water submersion and heavy rain, protecting your solar system and maintaining ideal performance.

Can MC4 Connectors Handle High Voltage Installations Safely?

Yes, MC4 connectors handle high voltage installations safely. They’re rated up to 1500V DC, with a robust design that includes waterproof seals and UV-resistant materials, guaranteeing reliable performance even in harsh conditions. Their tight locking mechanism prevents accidental disconnections, and their electrical ratings, including current capacity up to 70A, ensure safe operation across various solar setups. Always make certain proper installation and adhere to manufacturer specifications for maximum safety.

Are MC4 Connectors Compatible With All Solar Panel Brands?

Yes, MC4 connectors are compatible with most solar panel brands because they follow a universal standard recognized in the industry. You can easily connect panels from different manufacturers using these connectors, thanks to their standardized design and secure snap-lock mechanism. Just guarantee the connectors match the wire gauge and voltage requirements of your panels. This compatibility simplifies your installation, making it straightforward to expand or modify your solar setup later.

What Maintenance Is Required for MC4 Connectors Over Time?

Think of MC4 connectors like trusty old Swiss watches—requiring regular care to keep ticking smoothly. Over time, you should inspect them for dirt, corrosion, or damage, especially after harsh weather. Keep the contacts clean with a soft brush or cloth, and apply dielectric grease if needed to prevent moisture buildup. Guarantee the locking mechanism works properly and replace damaged connectors promptly to maintain ideal performance and safety.

How Do I Troubleshoot Connection Issues With MC4 Connectors?

To troubleshoot connection issues with MC4 connectors, start by inspecting the fittings for dirt, corrosion, or damage. Make certain the connectors are fully snapped together and locked securely. Check the wires for breaks or loose connections, and verify that the contacts are clean and properly seated. Use a multimeter to test continuity and voltage. If problems persist, disconnect and reseat the connectors, or replace damaged parts to restore proper function.

Conclusion

In the world of solar power, MC4 connectors are your reliable bridge, linking panels to potential. They’re the sturdy threads weaving durability, safety, and performance into your system’s fabric. When you understand their basics, you’re empowering your solar journey—like a captain steering through clear waters. So, embrace these connectors, handle them with care, and watch your solar setup flourish like a garden in full bloom, shining bright with confidence and clarity.